The consequences of NVIDIA’s change of manufacturing plants to the US

Supply chains depend greatly on geopolitical events and it’s uncertainty.

It appears NVIDIA is shifting its approach for manufacturing out of the U.S to in house because it seeks to cut overseas supply chains associated with customs, delays, and political risks. Redesigning the geography of resources allows NVIDIA to have better control over production by means of just in case order fulfillment by USA and Canadian borders.

Logistics and distribution are also managed in Canada and the US which means that NVIDIA can remove extra fees associated with third-party logistics and cut down drastically on the time it takes to get new goods to stores within North America. This new change helps NVIDIA boost their performance and efficiency and also their market standing.

Directly Overseeing And Having Control Over The Manufacturing Processes

Staying in touch with the people better known as supply chain managers helps a business figure out the best way of distributing all the resources including money, human labor, and time to max productivity while maintaining the efficiency.

NVIDIA now has more control over training sessions which allows them to build their windows over their heads and also helps them design product which have better chances of success and allow them to make brilliant which pay off handsomely.

Benefits & Importance

Supply chain resilience: Reduced exposure to geopolitical risk (e.g., Taiwan-China tensions, tariffs).�

Regulatory safeguards: Avoidance of shifting tariffs and import restrictions; strengthens ties with government policy.

Economic & workforce growth: Hundreds of thousands of U.S. jobs, from factory roles to high-tech engineering, especially in Texas and Arizona.

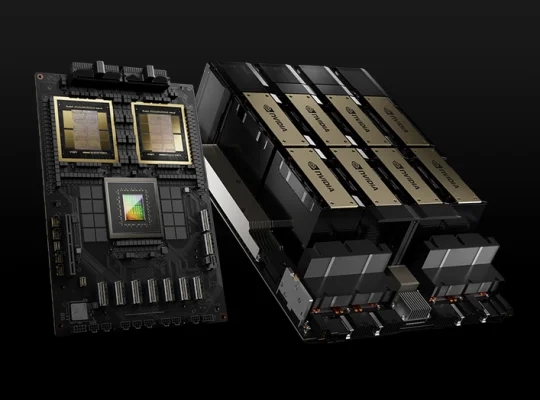

Technological momentum: Aligns chip production with next-gen AI data center growth—promoting U.S. leadership in AI infrastructure.

Conclusion:

Nvidia’s strategic shift towards U.S.-based manufacturing reflects more than patriotism—it is a multifaceted move to enhance supply chain resilience, leverage policy support, and lead in the AI infrastructure race. While U.S. production brings higher costs and longer timelines, smart implementation—through partnerships, automation, and policy alignment—can drive sustainable growth and innovation.